Your Complete Fluid Power Resource

When working in the fluid power industry, you need a partner who can provide more than just standard hydraulic and pneumatic fluid power repair components and technical advice; you need an experienced team who can deliver integrated fluid power solutions.

Hydraulic Pump, Motor, Valve and Cylinder Repairs

The Applied Fluid Power family of companies has state-of-the-art repair facilities for pumps, motors, valves and cylinders in varying size and horsepower. Our factory-trained technicians, OE parts and advanced equipment keep your facilities running.

Our hydraulic pump, motor, valve and cylinder repair capabilities include:

|

|

Replacement Hydraulic Hose Assemblies on Demand

Many of the Applied Fluid Power companies are certified Eaton Aeroquip Hose Centers offering the highest level of quality and cleanliness with automated hose cutting and kitting capabilities, certified hose technicians, custom protective ending for transport and hose cleaning upon manufacture. We offer high-quality hydraulic, pneumatic and fluid transfer hoses and fittings, with 3,500 commonly-used combinations in stock, including:

|

|

High-Velocity Oxygen Fuel (HVOF) System: An Environmentally Safe Thermal Spray Chroming Process for Extending the life of Hydraulic Cylinder Rods

Applied Fluid Power is a pioneer in High-Velocity Oxygen Fuel (HVOF) Cylinder Rod Resurfacing. Our team has invested in the best equipment available to bring you the cleanest and most environmentally-friendly thermal spray method for hydraulic actuators. The HVOF process utilizes a material in powder form that is injected into a flame of supersonic gas. The material softens in the flame and forms a dense coating on the substrate.

The HVOF process eliminates the use of chromic acid solutions, which are known carcinogens and can cause a host of other health problems. It also improves performance of cylindrical metal parts, dramatically lengthening component and seal life. This coating:

|

Estimated cylinder life improvement is as high as five times that of chrome, which means less opportunity for downtime.

Custom Design and Manufacture of Hydraulic Power Units

The Applied Fluid Power network offers Hydraulic Power Unit solutions that are economical, efficient and tailored for the particular task at hand. Our team of certified engineers is versed in both open loop and closed loop control systems as well as feedback control systems. We have experience in various mobile and industrial applications, including:

|

|

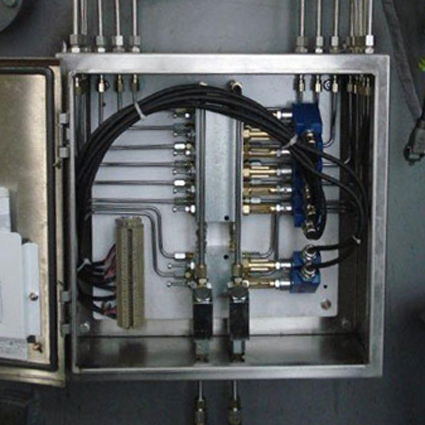

Custom Hydraulic Manifolds for Petroleum, Synthetic or High Water-Based Fluids

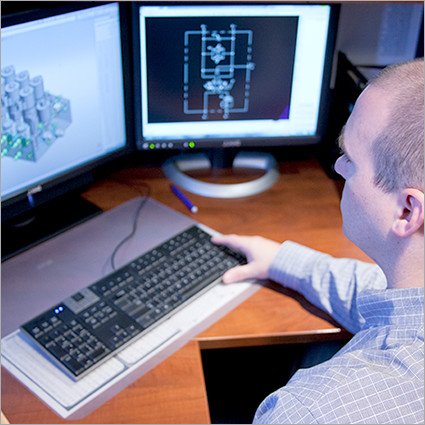

Using the latest CAD software and our years of experience designing mobile equipment, hydraulic circuits and manifolds, our team develops practical and efficient cartridge valve manifolds. CAD technology makes revisions and redesigns easy and quick, reducing the time from drawing board to manufacturing. The CAD drawings are then used to quickly work with the end user to fine tune the design to perfectly fit the application.

Most of our manifolds are made of 6061-T6 aluminum, however, we also use ductile iron and steel when needed or requested. Our machinery has the capacity for manifolds up to about 10”x10”x16” and quantities from one to 1000.

Our CNC equipment is programmed and ready for rapid and repeatable set ups so we can easily handle short runs and partial releases of larger orders. We also have the latest equipment (high horsepower and rpm, pallet changers, and coolant through the spindle) to be cost effective on high volume runs.

Fluid Power Systems and Electronic Controls Integration

From concept to completion, the Applied Fluid Power companies design and build custom fluid power systems for a diverse selection of industries using AutoCAD and 3D software. Additionally, systems are manufactured in ISO certified facilities.

Clean Room Capabilities

The Applied Fluid Power network includes a Class 1,000 cleanroom and a Class 100 hood, providing the ideal assembly environment for semi-conductor and medical application projects.

Electro-Hydraulic and Electro-Pneumatic Control Packages and Test Stands

As Certified Eaton P1 Integrators, the Applied Fluid Power companies provide access to the industry’s finest electro-hydraulic experts across the country to design electro-hydraulic systems that optimize performance. Our team has the broadest combined set of electrical and hydraulic products available anywhere, including rapid prototypes that refine solutions and dramatically reduce overall time and cost. As the country’s leading single-source electro-hydraulic supplier, our network offers a lower total cost of ownership in every project.

Applied Fluid Power companies design and build electronic control packages to manage your machine performance, including:

|

|

|

Custom Filtration Systems (fabricated Filtrating Systems and Purifiers)

The Applied Fluid Power network provides SKF and Lincoln lubrication products and support, as well as:

|

|

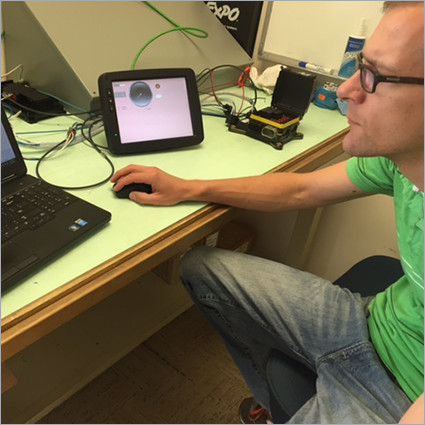

Fluid Sampling and Analysis: Photo Micrograph, Particle Counter and Water Sensor

New oil can be one of the worst sources of particulate and water contamination. Our team can analyze fluids to provide insight into system conditions and help predict and prevent fluid contamination-related issues. Improving fluid cleanliness means reduced downtime, more reliable equipment, longer fluid life, fewer maintenance hours and reduced need for costly component replacement or repair. The Applied Fluid Power network of companies can help you create a plan to achieve and maintain target fluid cleanliness for your operation.

Hydraulic Systems Retrofits: Updating Systems to Current Technology and Standards

Retrofit systems allow you to replace existing out-of-date systems with more modern products. Current versions of electric motors and hydraulic pumps are typically more efficient, cost less to replace or repair and require less maintenance than older products. These higher-efficiency components use less power to operate, which lowers operating costs. Additionally, newer systems typically use standardized components that make spare part management and maintenance easier and reduce downtime waiting for pumps to be rebuilt or repaired.

Lube Oil Systems

Our network designs, builds and installs a broad range of centralized lubrication systems, including:

|

|

Among our network of companies, we represent some of the top lubrication equipment manufacturers, including Bijur Delimon, Alemite, Farval, Graco, Oil-Rite, Dropsa and Vogel. Through these manufacturers, our team is able to stock and service the following products:

|

|